GTM Fire is your trusted partner for fire hydrant system installations in India. With our expertise and dedication, we provide top-notch fire hydrant systems designed specifically for industries. Our comprehensive range of services covers installation, maintenance, and annual maintenance contracts (AMC) for fire hydrant systems in industrial settings.

At GTM Fire, we understand the critical importance of fire safety in industries. Our team of highly skilled professionals is committed to delivering reliable and efficient fire hydrant systems that meet industry standards and regulations.

When it comes to industries, we recognize the unique requirements and challenges they face. That's why our tailored fire hydrant systems are specifically designed to address the needs of industrial environments. Our systems are meticulously installed, ensuring seamless integration with your existing infrastructure.

As industry leaders in fire hydrant system installations, we offer a wide range of services. From initial consultation to system design and installation, we handle every aspect with utmost professionalism. Our experienced technicians utilize cutting-edge technology and high-quality materials to ensure the highest level of performance and durability.

In addition to installation, we provide comprehensive maintenance services for fire hydrant systems in industries. Our dedicated team conducts regular inspections, testing, and preventive maintenance to ensure your system remains in optimal condition. We understand the importance of minimal downtime, and our efficient maintenance services keep your fire hydrant system ready for any emergency.

To further streamline your fire safety requirements, we offer annual maintenance contracts (AMC) tailored to the specific needs of your industry. Our AMC services provide you with peace of mind, knowing that your fire hydrant system is in safe hands. Our team follows a proactive approach, conducting periodic checks and promptly addressing any potential issues, ensuring maximum reliability and compliance.

At GTM Fire, we take pride in our commitment to excellence. We prioritize customer satisfaction and guarantee the highest level of professionalism and integrity in all our services. When you choose us, you can be confident that you are partnering with a reliable and trusted provider of fire hydrant systems for industries in India.

Don't compromise on safety. Contact GTM Fire today and let us safeguard your industry with our top-quality fire hydrant systems and expert services. Trust us to keep your business protected from fire hazards, ensuring the safety of your employees and assets.

The installation process of a fire hydrant system for industries typically includes the following steps:

1. Design and planning: An experienced fire protection engineer or consultant assesses the facility's needs and develops a detailed plan for the fire hydrant system installation, considering factors such as the size of the facility, fire hazards, and regulatory requirements.

2. Permitting and approvals: Obtain necessary permits and approvals from local authorities having jurisdiction (AHJ) before commencing the installation. Compliance with local fire codes and regulations is crucial.

3. Water supply assessment: Determine the water supply source for the fire hydrant system. This may involve evaluating the available water pressure, flow rates, and reservoir capacities to ensure adequate water supply during emergencies.

4. Hydrant placement and layout: Identify suitable locations for fire hydrants based on factors like facility layout, accessibility, and coverage requirements. The placement should ensure that hydrants are easily accessible to firefighters and strategically positioned to cover the entire facility.

5. Excavation and pipe installation: Excavate trenches to lay underground pipes connecting the hydrants. The pipes should be durable and capable of withstanding high water pressure. Install valves, fittings, and any required backflow prevention devices as per the design specifications.

6. Hydrant installation: Install the fire hydrants at designated locations according to the layout plan. This involves mounting the hydrant on a concrete pad or anchoring it securely to the ground. Ensure proper connection to the underground pipes and verify that the hydrant operates smoothly.

7. Pressure testing and flushing: Conduct pressure testing to verify the integrity of the system and ensure that it can withstand the required pressure levels. Flushing the hydrant system removes any debris or sediments that may have accumulated during installation.

8. Backfilling and restoration: Once the system passes the pressure test, backfill the excavated trenches and restore the surface, ensuring proper compaction. The area around each hydrant should be clearly marked and easily visible.

9. Inspection and certification: Arrange for a final inspection by the AHJ to verify compliance with regulations and approve the installation. Obtain the necessary certification or documentation to demonstrate that the fire hydrant system meets the required standards.

10. Maintenance and testing: Regularly inspect, test, and maintain the fire hydrant system to ensure its proper functioning. This includes periodic inspections, flow testing, and maintenance of valves, hydrant components, and associated equipment.

Remember that the installation process may vary depending on local regulations, specific industry requirements, and the complexity of the facility. It's important to consult with experts and follow all applicable codes and standards during the installation of a fire hydrant system for industries.

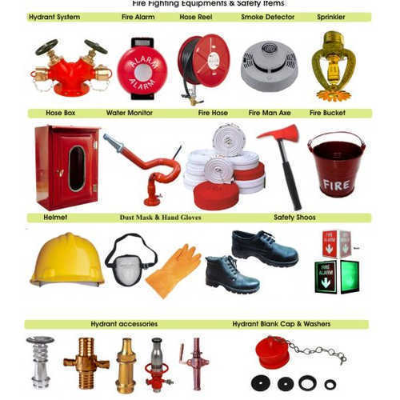

The installation of a fire hydrant system for industries typically requires several accessories to ensure proper functionality and compliance with safety standards. Here are some commonly used accessories:

1. Fire Hydrants: These are the main components of the system and include above-ground hydrants with outlets for connecting hoses. Hydrants are available in various types, such as pillar hydrants, post hydrants, or wall-mounted hydrants, depending on the specific installation requirements.

2. Hydrant Valves: These valves control the flow of water within the hydrant system. They include main control valves, which regulate water supply to the entire system, and outlet valves located on individual hydrants for connecting hoses.

3. Fire Hoses: High-quality fire hoses are essential for connecting to hydrants and delivering water to the fire. These hoses are usually made of durable materials such as rubber or synthetic fibers and should be compatible with the system's water pressure and flow requirements.

4. Hose Couplings: These are fittings used to connect fire hoses to hydrants or other firefighting equipment. Couplings ensure a secure and leak-free connection between the hose and the hydrant or nozzle.

5. Standpipe Systems: In some industrial settings, standpipe systems are installed alongside fire hydrants. These systems consist of vertical pipes with outlets at various levels, allowing firefighters to connect hoses at different heights within the building or facility.

6. Backflow Prevention Devices: Backflow preventers are crucial to prevent the reverse flow of water from the fire hydrant system back into the main water supply. These devices protect the potable water system from contamination and maintain water quality.

7. Hydrant Markers: Visible markers or signs are placed near each hydrant to ensure easy identification. These markers help firefighters locate hydrants quickly during emergencies.

8. Pressure Gauges: Pressure gauges are used to measure and monitor the water pressure within the system. They are typically installed at key points, such as the hydrant valve or control valve, to ensure the system operates within the desired pressure range.

9. Fire Hydrant Wrenches: These specialized tools are required for opening and closing hydrant valves during maintenance or firefighting operations. They enable easy operation of the hydrant valves and should be kept readily accessible.

10. Locking Devices: Locking devices, such as lockable caps or chains, can be used to secure the hydrant valves and prevent unauthorized use or tampering.

Remember that the specific accessories required may vary depending on the design and regulations applicable to your industry and location. It's important to consult with fire protection experts and adhere to local codes and standards when selecting and installing accessories for a fire hydrant system in an industrial setting.

Fire hydrant systems offer several benefits when installed in industrial settings. Here are some key advantages:

1. Rapid Fire Suppression: Fire hydrant systems provide an immediate and reliable water supply for firefighting. They allow firefighters to quickly connect hoses and deliver large volumes of water to suppress and control fires, minimizing the spread of flames and reducing potential damage to property and equipment.

2. Increased Safety: Fire hydrant systems enhance the safety of industrial facilities by providing an accessible and readily available firefighting resource. They enable trained personnel to initiate firefighting efforts promptly, potentially preventing small fires from escalating into major incidents.

3. Comprehensive Coverage: By strategically placing fire hydrants throughout the facility, the system ensures comprehensive coverage, allowing firefighters to reach fires quickly from multiple access points. This helps minimize response time and ensures that no area is too far from a hydrant, improving overall firefighting effectiveness.

4. Water Supply Reliability: Fire hydrant systems require a dedicated water supply, such as a municipal water source or on-site water storage tanks. This ensures a reliable water source for firefighting operations, reducing dependency on external factors like water pressure fluctuations or equipment failures.

5. Compliance with Regulations: Many industrial facilities are legally required to have fire hydrant systems as per local fire codes and regulations. Installing and maintaining these systems helps businesses comply with safety standards and demonstrates a commitment to protecting employees, property, and the surrounding community.

6. Flexibility and Scalability: Fire hydrant systems can be designed to meet the specific needs of different industrial sites. They can be customized based on the size of the facility, potential fire hazards, and regulatory requirements. Additionally, these systems can be expanded or modified as the facility evolves or expands, ensuring ongoing fire protection.

7. Supplementary Firefighting Equipment: Fire hydrant systems can complement other fire safety measures in industrial settings, such as sprinkler systems or fire extinguishers. They provide an additional layer of defense and can be used in conjunction with other firefighting equipment to enhance overall fire response capabilities.

8. Emergency Response Support: Fire hydrant systems facilitate collaboration with local fire departments during emergencies. Firefighters are familiar with hydrant systems and can quickly connect their hoses to the hydrants, thus streamlining the response and coordination efforts during firefighting operations.

It's important to note that fire hydrant systems should be regularly inspected, tested, and maintained to ensure their continued functionality. This includes routine inspections, flow testing, and maintenance of hydrants, valves, and associated equipment as per manufacturer guidelines and local regulations.

Fire Fighting Equipments

Fire Fighting Equipments Fire Alarm

Fire Alarm Fire Hydrant System

Fire Hydrant System Fire Extinguisher

Fire Extinguisher Fire Detection System

Fire Detection System Fire Detector

Fire Detector Smoke Detector

Smoke Detector Fire sprinkler

Fire sprinkler Fire Suppression

Fire Suppression Fire Safety

Fire Safety Fire Protection Equipments

Fire Protection Equipments Fire Door

Fire Door Gas Suppression System

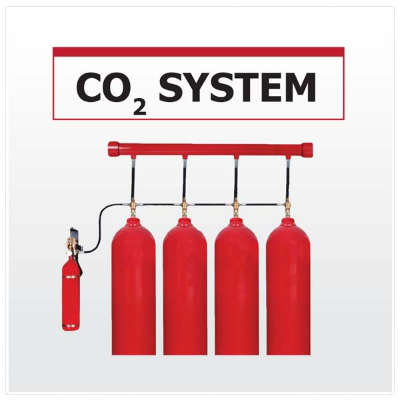

Gas Suppression System Co2 Fire Suppression System

Co2 Fire Suppression System FM 200 Fire Suppression System

FM 200 Fire Suppression System Fire Hydrant System for Building

Fire Hydrant System for Building Fire Hydrant System for Hospital

Fire Hydrant System for Hospital Fire Hydrant System for Offices

Fire Hydrant System for Offices Fire Hydrant System for Warehouse

Fire Hydrant System for Warehouse Fire Hydrant System for Factory

Fire Hydrant System for Factory Fire Hydrant System for School

Fire Hydrant System for School Fire Hydrant System for Hotels

Fire Hydrant System for Hotels Fire Hydrant System for Laboratory

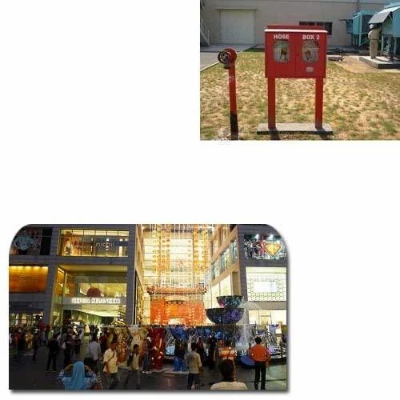

Fire Hydrant System for Laboratory Fire Hydrant System for Malls

Fire Hydrant System for Malls Fire Hydrant System for Theatres

Fire Hydrant System for Theatres Fire Hydrant System for Housing Society

Fire Hydrant System for Housing Society Fire Hydrant System for Transformer

Fire Hydrant System for Transformer Fire Hydrant System for Shopping Complex

Fire Hydrant System for Shopping Complex Fire Hydrant System for Construction Site

Fire Hydrant System for Construction Site Fire Sprinkler System for Buildings

Fire Sprinkler System for Buildings Fire Sprinkler System for Retail Store

Fire Sprinkler System for Retail Store Fire Sprinkler System for Shopping Complex

Fire Sprinkler System for Shopping Complex Fire Sprinkler System for Electrical Room

Fire Sprinkler System for Electrical Room Fire Sprinkler System for Basement

Fire Sprinkler System for Basement Fire Sprinkler System for Theaters

Fire Sprinkler System for Theaters Fire Sprinkler System for Garage

Fire Sprinkler System for Garage Fire Sprinkler System for Home

Fire Sprinkler System for Home Fire Sprinkler System for Restaurant

Fire Sprinkler System for Restaurant Fire Sprinkler System for Malls

Fire Sprinkler System for Malls Fire Sprinkler System for Laboratories

Fire Sprinkler System for Laboratories Fire Sprinkler System for Hotels

Fire Sprinkler System for Hotels Fire Sprinkler System for Factories

Fire Sprinkler System for Factories Fire Sprinkler System for Hospital

Fire Sprinkler System for Hospital Fire Sprinkler System for Warehouse

Fire Sprinkler System for Warehouse Fire Sprinkler System for Office

Fire Sprinkler System for Office Fire Alarm System for Factory

Fire Alarm System for Factory Fire Alarm System for Office

Fire Alarm System for Office Fire Alarm System for Warehouse

Fire Alarm System for Warehouse Fire Alarm System for Home

Fire Alarm System for Home Fire Alarm System for Residential Building

Fire Alarm System for Residential Building Fire Alarm System for Office Building

Fire Alarm System for Office Building Fire Alarm System for Building

Fire Alarm System for Building Fire Alarm System for Business

Fire Alarm System for Business Fire Alarm System for Commercial Building

Fire Alarm System for Commercial Building Fire Alarm System for Restaurant

Fire Alarm System for Restaurant Fire Alarm System for Hospital

Fire Alarm System for Hospital Fire Alarm System for Schools

Fire Alarm System for Schools Fire Alarm System for Hotels

Fire Alarm System for Hotels Fire Alarm System for Mall

Fire Alarm System for Mall Fire Alarm System for Airport

Fire Alarm System for Airport Fire Alarm System for Cinema Hall

Fire Alarm System for Cinema Hall Fire Alarm System for Home care

Fire Alarm System for Home care Fire Alarm System for Shopping Complex

Fire Alarm System for Shopping Complex Fire Alarm System for Apartment

Fire Alarm System for Apartment Fire Alarm System for Laboratory

Fire Alarm System for Laboratory Fire Alarm System for Retail Store

Fire Alarm System for Retail Store Fire Alarm System for Food Court

Fire Alarm System for Food Court Fire Alarm System for Kitchen

Fire Alarm System for Kitchen Fire Alarm System for Data Center

Fire Alarm System for Data Center Fire Alarm System for Coaching Institute

Fire Alarm System for Coaching Institute Fire Alarm System for Auditorium

Fire Alarm System for Auditorium