GTM Fire is your premier gas suppression system installation company in India. We specialize in providing cutting-edge solutions for a wide range of applications, including gas suppression systems for server rooms, electrical rooms, and more. With our expertise and dedication to safety, you can trust us to safeguard your valuable assets.

At GTM Fire, we understand the critical importance of protecting your sensitive equipment from the devastating effects of fire. That's why we offer top-of-the-line gas suppression systems that are designed to quickly and effectively suppress fires without causing any harm to your valuable assets. Our systems are meticulously engineered to meet the highest industry standards, ensuring optimal performance and reliability.

When it comes to gas suppression system installation, we have a team of highly skilled professionals who are trained to handle even the most complex projects. Whether it's a small server room or a large-scale industrial facility, we have the expertise and experience to deliver tailored solutions that meet your specific requirements. Our installation services are prompt, efficient, and carried out with utmost precision to ensure seamless integration into your existing infrastructure.

As an authorized partner of leading manufacturers, we offer a wide range of gas suppression system panels to suit your needs. Our panels are equipped with advanced features and intuitive controls, allowing for easy monitoring and management of your suppression system. With our solutions, you can have peace of mind knowing that your assets are protected by the latest technology.

We understand that budget is an important factor in any project. That's why we strive to provide competitive pricing without compromising on quality. Our gas suppression system prices are transparent and tailored to fit your budgetary constraints. Additionally, we offer comprehensive maintenance and inspection services to ensure that your system remains in optimal condition, ready to respond swiftly in case of an emergency.

At GTM Fire, we take pride in being one of the leading gas suppression system suppliers in India. We have established strong partnerships with reputable manufacturers and suppliers, enabling us to source top-quality components and equipment. Our products are compliant with NFPA (National Fire Protection Association) standards and incorporate innovative technologies like NOVEC (a clean agent) for enhanced efficiency and safety.

Whether you are looking for gas suppression system installation, inspection, or maintenance services, GTM Fire is your trusted partner. With our unwavering commitment to excellence, exceptional customer service, and industry expertise, we strive to exceed your expectations. Contact us today to discuss your requirements and let us provide you with a reliable and efficient gas suppression system solution.

Gas suppression systems have a wide range of applications in India, primarily aimed at protecting critical infrastructure, and valuable assets, and ensuring the safety of personnel. Here are some key areas where gas suppression systems are commonly used:

1. Gas suppression systems for Server Rooms and Data Centers: Gas suppression systems are crucial for safeguarding server rooms and data centers, where the risk of fire can lead to data loss and operational downtime. These systems can quickly suppress fires without causing damage to sensitive equipment, ensuring uninterrupted operation.

2. Gas suppression systems for Electrical Rooms: Electrical equipment rooms house vital infrastructure, such as switchgear, transformers, and control panels. Gas suppression systems are essential in these areas to prevent electrical fires that can result from short circuits or equipment malfunctions.

3. Gas suppression systems for Laboratories and Research Facilities: Gas suppression systems are extensively used in laboratories and research facilities where the presence of flammable chemicals or sensitive experiments increases the risk of fire. These systems provide rapid fire suppression while minimizing damage to delicate equipment and valuable research.

4. Gas suppression systems for Industrial Facilities: Manufacturing plants, warehouses, and industrial facilities often have high fire risk due to the presence of flammable materials, machinery, and processes. Gas suppression systems are employed to protect these environments and minimize the potential for fire-related accidents and losses.

5. Gas suppression systems for Museums and Art Galleries: Cultural institutions house priceless artifacts, historical documents, and artwork susceptible to fire damage. Gas suppression systems are deployed in these facilities to provide a fast and efficient response to fires while minimizing the potential for water damage or harmful residue.

6. Gas suppression systems for Hospitals and Healthcare Facilities: Gas suppression systems are utilized in critical areas of hospitals and healthcare facilities, such as operating rooms, MRI suites, and medical equipment storage areas. These systems ensure the safety of patients, staff, and expensive medical equipment in the event of a fire.

7. Gas suppression systems for Telecommunication Facilities: Gas suppression systems are installed in telecommunication facilities, including telecommunication rooms, data centers, and network operation centers. These systems protect critical communication infrastructure and prevent service disruptions.

8. Gas suppression systems for Banks and Financial Institutions: Financial institutions house valuable assets, sensitive data, and critical infrastructure. Gas suppression systems are employed to protect these assets and minimize the risk of fire-related disruptions to banking operations.

It's important to note that the specific gas suppression system employed may vary depending on the application and the nature of the environment. Professional assessment, design, and installation are essential to ensure the system is tailored to the specific requirements and complies with relevant safety standards.

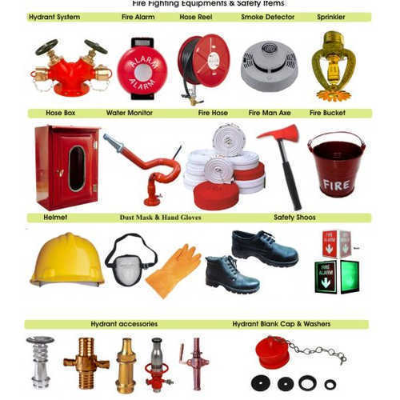

Fire Fighting Equipments

Fire Fighting Equipments Fire Alarm

Fire Alarm Fire Hydrant System

Fire Hydrant System Fire Extinguisher

Fire Extinguisher Fire Detection System

Fire Detection System Fire Detector

Fire Detector Smoke Detector

Smoke Detector Fire sprinkler

Fire sprinkler Fire Suppression

Fire Suppression Fire Safety

Fire Safety Fire Protection Equipments

Fire Protection Equipments Fire Door

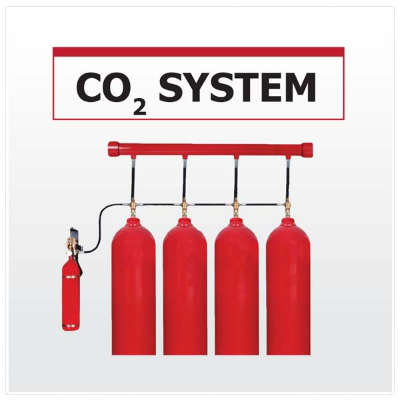

Fire Door Co2 Fire Suppression System

Co2 Fire Suppression System FM 200 Fire Suppression System

FM 200 Fire Suppression System Fire Hydrant System for Building

Fire Hydrant System for Building Fire Hydrant System for Hospital

Fire Hydrant System for Hospital Fire Hydrant System for Offices

Fire Hydrant System for Offices Fire Hydrant System for Warehouse

Fire Hydrant System for Warehouse Fire Hydrant System for Factory

Fire Hydrant System for Factory Fire Hydrant System for School

Fire Hydrant System for School Fire Hydrant System for Hotels

Fire Hydrant System for Hotels Fire Hydrant System for Laboratory

Fire Hydrant System for Laboratory Fire Hydrant System for Malls

Fire Hydrant System for Malls Fire Hydrant System for Theatres

Fire Hydrant System for Theatres Fire Hydrant System for Housing Society

Fire Hydrant System for Housing Society Fire Hydrant System for Transformer

Fire Hydrant System for Transformer Fire Hydrant System for Shopping Complex

Fire Hydrant System for Shopping Complex Fire Hydrant System for Industries

Fire Hydrant System for Industries Fire Hydrant System for Construction Site

Fire Hydrant System for Construction Site Fire Sprinkler System for Buildings

Fire Sprinkler System for Buildings Fire Sprinkler System for Retail Store

Fire Sprinkler System for Retail Store Fire Sprinkler System for Shopping Complex

Fire Sprinkler System for Shopping Complex Fire Sprinkler System for Electrical Room

Fire Sprinkler System for Electrical Room Fire Sprinkler System for Basement

Fire Sprinkler System for Basement Fire Sprinkler System for Theaters

Fire Sprinkler System for Theaters Fire Sprinkler System for Garage

Fire Sprinkler System for Garage Fire Sprinkler System for Home

Fire Sprinkler System for Home Fire Sprinkler System for Restaurant

Fire Sprinkler System for Restaurant Fire Sprinkler System for Malls

Fire Sprinkler System for Malls Fire Sprinkler System for Laboratories

Fire Sprinkler System for Laboratories Fire Sprinkler System for Hotels

Fire Sprinkler System for Hotels Fire Sprinkler System for Factories

Fire Sprinkler System for Factories Fire Sprinkler System for Hospital

Fire Sprinkler System for Hospital Fire Sprinkler System for Warehouse

Fire Sprinkler System for Warehouse Fire Sprinkler System for Office

Fire Sprinkler System for Office Fire Alarm System for Factory

Fire Alarm System for Factory Fire Alarm System for Office

Fire Alarm System for Office Fire Alarm System for Warehouse

Fire Alarm System for Warehouse Fire Alarm System for Home

Fire Alarm System for Home Fire Alarm System for Residential Building

Fire Alarm System for Residential Building Fire Alarm System for Office Building

Fire Alarm System for Office Building Fire Alarm System for Building

Fire Alarm System for Building Fire Alarm System for Business

Fire Alarm System for Business Fire Alarm System for Commercial Building

Fire Alarm System for Commercial Building Fire Alarm System for Restaurant

Fire Alarm System for Restaurant Fire Alarm System for Hospital

Fire Alarm System for Hospital Fire Alarm System for Schools

Fire Alarm System for Schools Fire Alarm System for Hotels

Fire Alarm System for Hotels Fire Alarm System for Mall

Fire Alarm System for Mall Fire Alarm System for Airport

Fire Alarm System for Airport Fire Alarm System for Cinema Hall

Fire Alarm System for Cinema Hall Fire Alarm System for Home care

Fire Alarm System for Home care Fire Alarm System for Shopping Complex

Fire Alarm System for Shopping Complex Fire Alarm System for Apartment

Fire Alarm System for Apartment Fire Alarm System for Laboratory

Fire Alarm System for Laboratory Fire Alarm System for Retail Store

Fire Alarm System for Retail Store Fire Alarm System for Food Court

Fire Alarm System for Food Court Fire Alarm System for Kitchen

Fire Alarm System for Kitchen Fire Alarm System for Data Center

Fire Alarm System for Data Center Fire Alarm System for Coaching Institute

Fire Alarm System for Coaching Institute Fire Alarm System for Auditorium

Fire Alarm System for Auditorium