GTM Fire is India's premier provider of Fire Sprinkler System installations. We specialize in offering top-of-the-line fire sprinkler solutions specifically designed for laboratories. Our comprehensive range of services includes laboratory fire sprinkler system installation, maintenance, and annual maintenance contracts (AMC) to ensure the safety and security of your valuable assets.

When it comes to laboratory fire safety, precision and reliability are of utmost importance. At GTM Fire, we understand the unique requirements of laboratory environments and provide tailored fire sprinkler systems that meet the highest industry standards. Our team of experienced professionals is adept at designing and installing cutting-edge fire sprinkler systems that integrate seamlessly with your laboratory infrastructure.

Our laboratory fire sprinkler systems are meticulously engineered to detect and suppress fires effectively, minimizing the risk of damage to equipment and crucial research. With a focus on precision and efficiency, our systems are designed to address the specific hazards found in laboratories, offering optimal protection against chemical, electrical, and other types of fires.

At GTM Fire, we take pride in our commitment to quality and customer satisfaction. Our dedicated technicians provide comprehensive installation services, ensuring that your laboratory fire sprinkler system is seamlessly integrated into your facility. We understand the critical nature of laboratory operations and work diligently to minimize disruptions during the installation process.

In addition to installation, we also offer comprehensive maintenance services for your laboratory fire sprinkler system. Our AMC packages are designed to keep your system in optimal working condition, providing regular inspections, testing, and maintenance to ensure reliable performance. With GTM Fire, you can have peace of mind knowing that your fire sprinkler system is well-maintained and ready to safeguard your laboratory at all times.

When it comes to laboratory fire safety, trust the experts at GTM Fire. Contact us today to learn more about our specialized fire sprinkler systems for laboratories and discover how we can enhance the safety and security of your valuable assets.

Installing a fire sprinkler system in a laboratory is an essential safety measure to protect the occupants and valuable equipment from fire hazards. Here's a general outline of the installation process for a fire sprinkler system in laboratories:

1. Design and Planning:

- Hire a professional fire protection engineer or a licensed sprinkler system contractor to design the system based on the specific requirements and codes applicable to laboratory settings.

- Consider the laboratory layout, occupancy type, hazard level, and any unique features or equipment that may affect the system design.

2. Obtain Permits and Approvals:

- Contact the local fire department or the relevant authority having jurisdiction to obtain the necessary permits and approvals for the installation.

- Provide the required documentation, including design plans, hydraulic calculations, equipment specifications, and other supporting documents.

3. Equipment Selection:

- Based on the design, select the appropriate fire sprinkler heads, valves, pipes, and other system components that comply with the laboratory's requirements and applicable codes.

- Ensure that the materials used are compatible with the specific hazards present in the laboratory, such as corrosive chemicals or high-temperature environments.

4. Installation:

- Prepare the work area by removing any obstacles, ensuring proper access to walls, ceilings, and floors where the sprinkler system will be installed.

- Install the main water supply connection and backflow prevention devices as per local regulations.

- Install the pipes and fittings following the design plans, ensuring proper support and alignment.

- Mount the sprinkler heads according to the design specifications, considering the ceiling height, spacing requirements, and specific hazard areas.

- Connect the sprinkler heads to the distribution pipes using appropriate fittings and ensure proper sealing to prevent leaks.

5. Water Supply and Alarm System:

- Connect the sprinkler system to a reliable water supply, such as the municipal water line or a dedicated water storage tank.

- Install a fire department connection (FDC) to allow firefighters to supplement the water supply during emergencies.

- Integrate the fire sprinkler system with the building's fire alarm system, ensuring effective communication and coordination between the two systems.

6. Testing and Commissioning:

- Conduct a thorough inspection of the installed system to ensure compliance with the design, codes, and regulations.

- Perform hydraulic tests to validate the system's water flow, pressure, and distribution.

- Coordinate with the local authorities for the final inspection and obtain the necessary certifications and approvals.

7. Maintenance and Regular Inspections:

- Develop a maintenance plan for the fire sprinkler system, including periodic inspections, testing, and maintenance activities.

- Follow the manufacturer's guidelines and recommendations for system maintenance.

- Train laboratory staff on the proper use and maintenance of the system and provide education on fire safety practices.

It's important to note that the installation process may vary depending on the specific requirements, building codes, and local regulations applicable to your location. Therefore, it's always recommended to consult with professionals who specialize in fire protection engineering and adhere to the local regulations and guidelines throughout the installation process.

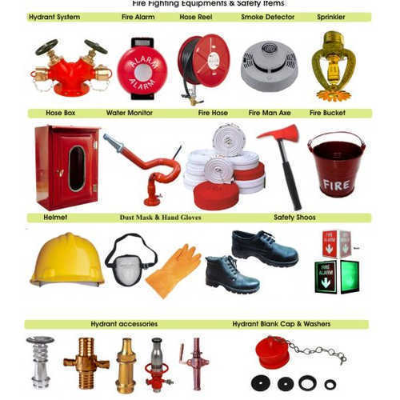

When installing a fire sprinkler system in a laboratory, there are several accessories and components that are typically required. These accessories help to enhance the functionality and effectiveness of the sprinkler system. Here are some common accessories used in the installation of a fire sprinkler system for laboratories:

1. Sprinkler Heads: Sprinkler heads are the most visible part of the system. They are available in various types, such as pendant, upright, and sidewall, and are designed to activate and discharge water when exposed to heat.

2. Piping: The piping system carries water from the water supply to the sprinkler heads. Common types of pipes used in fire sprinkler systems include steel, copper, and CPVC (Chlorinated Polyvinyl Chloride). The selection of the pipe material depends on factors such as the type of hazard, temperature, and local codes.

3. Fittings and Couplings: Fittings and couplings are used to connect and join sections of piping. They ensure a secure and leak-tight connection between pipes, sprinkler heads, valves, and other system components.

4. Valves: Valves are essential for controlling the flow of water in the sprinkler system. Common valves used include main control valves, alarm valves, check valves, and isolation valves. These valves allow for shutting off specific sections of the system for maintenance or repairs.

5. Water Supply Connection: The system requires a connection to a reliable water supply source. This can be a municipal water line, a dedicated water storage tank, or a pump system. Backflow prevention devices are also installed to prevent the contamination of the water supply.

6. Fire Department Connection (FDC): An FDC provides a connection point for firefighters to supplement the water supply during an emergency. It typically includes a check valve and connections for fire hoses.

7. Alarm Devices: Fire sprinkler systems are often integrated with fire alarm systems. Alarm devices such as flow switches, pressure switches, water flow alarms, and supervisory devices are installed to detect and signal the activation of the sprinkler system.

8. Pressure Gauges: Pressure gauges are used to monitor the water pressure within the sprinkler system. They are typically installed at strategic locations, such as on the main control valve or riser, to ensure proper water flow and pressure.

9. Hangers and Supports: Hangers and supports are used to secure and support the pipes in the correct position. They help maintain the proper alignment of the piping system and prevent sagging or misalignment.

10. Signage: Clear and visible signage should be installed to indicate the presence of a fire sprinkler system and provide instructions for its proper use during emergencies.

It's important to consult with a professional fire protection engineer or a licensed sprinkler system contractor to ensure that the selected accessories comply with the laboratory's specific requirements and adhere to relevant codes and regulations.

Fire Fighting Equipments

Fire Fighting Equipments Fire Alarm

Fire Alarm Fire Hydrant System

Fire Hydrant System Fire Extinguisher

Fire Extinguisher Fire Detection System

Fire Detection System Fire Detector

Fire Detector Smoke Detector

Smoke Detector Fire sprinkler

Fire sprinkler Fire Suppression

Fire Suppression Fire Safety

Fire Safety Fire Protection Equipments

Fire Protection Equipments Fire Door

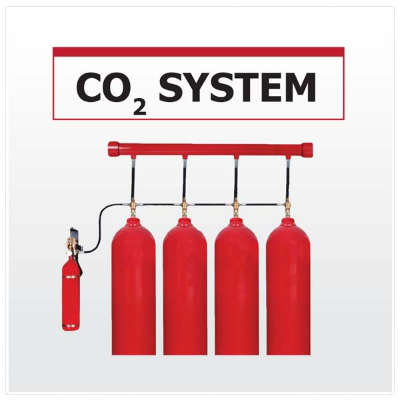

Fire Door Gas Suppression System

Gas Suppression System Co2 Fire Suppression System

Co2 Fire Suppression System FM 200 Fire Suppression System

FM 200 Fire Suppression System Fire Hydrant System for Building

Fire Hydrant System for Building Fire Hydrant System for Hospital

Fire Hydrant System for Hospital Fire Hydrant System for Offices

Fire Hydrant System for Offices Fire Hydrant System for Warehouse

Fire Hydrant System for Warehouse Fire Hydrant System for Factory

Fire Hydrant System for Factory Fire Hydrant System for School

Fire Hydrant System for School Fire Hydrant System for Hotels

Fire Hydrant System for Hotels Fire Hydrant System for Laboratory

Fire Hydrant System for Laboratory Fire Hydrant System for Malls

Fire Hydrant System for Malls Fire Hydrant System for Theatres

Fire Hydrant System for Theatres Fire Hydrant System for Housing Society

Fire Hydrant System for Housing Society Fire Hydrant System for Transformer

Fire Hydrant System for Transformer Fire Hydrant System for Shopping Complex

Fire Hydrant System for Shopping Complex Fire Hydrant System for Industries

Fire Hydrant System for Industries Fire Hydrant System for Construction Site

Fire Hydrant System for Construction Site Fire Sprinkler System for Buildings

Fire Sprinkler System for Buildings Fire Sprinkler System for Retail Store

Fire Sprinkler System for Retail Store Fire Sprinkler System for Shopping Complex

Fire Sprinkler System for Shopping Complex Fire Sprinkler System for Electrical Room

Fire Sprinkler System for Electrical Room Fire Sprinkler System for Basement

Fire Sprinkler System for Basement Fire Sprinkler System for Theaters

Fire Sprinkler System for Theaters Fire Sprinkler System for Garage

Fire Sprinkler System for Garage Fire Sprinkler System for Home

Fire Sprinkler System for Home Fire Sprinkler System for Restaurant

Fire Sprinkler System for Restaurant Fire Sprinkler System for Malls

Fire Sprinkler System for Malls Fire Sprinkler System for Hotels

Fire Sprinkler System for Hotels Fire Sprinkler System for Factories

Fire Sprinkler System for Factories Fire Sprinkler System for Hospital

Fire Sprinkler System for Hospital Fire Sprinkler System for Warehouse

Fire Sprinkler System for Warehouse Fire Sprinkler System for Office

Fire Sprinkler System for Office Fire Alarm System for Factory

Fire Alarm System for Factory Fire Alarm System for Office

Fire Alarm System for Office Fire Alarm System for Warehouse

Fire Alarm System for Warehouse Fire Alarm System for Home

Fire Alarm System for Home Fire Alarm System for Residential Building

Fire Alarm System for Residential Building Fire Alarm System for Office Building

Fire Alarm System for Office Building Fire Alarm System for Building

Fire Alarm System for Building Fire Alarm System for Business

Fire Alarm System for Business Fire Alarm System for Commercial Building

Fire Alarm System for Commercial Building Fire Alarm System for Restaurant

Fire Alarm System for Restaurant Fire Alarm System for Hospital

Fire Alarm System for Hospital Fire Alarm System for Schools

Fire Alarm System for Schools Fire Alarm System for Hotels

Fire Alarm System for Hotels Fire Alarm System for Mall

Fire Alarm System for Mall Fire Alarm System for Airport

Fire Alarm System for Airport Fire Alarm System for Cinema Hall

Fire Alarm System for Cinema Hall Fire Alarm System for Home care

Fire Alarm System for Home care Fire Alarm System for Shopping Complex

Fire Alarm System for Shopping Complex Fire Alarm System for Apartment

Fire Alarm System for Apartment Fire Alarm System for Laboratory

Fire Alarm System for Laboratory Fire Alarm System for Retail Store

Fire Alarm System for Retail Store Fire Alarm System for Food Court

Fire Alarm System for Food Court Fire Alarm System for Kitchen

Fire Alarm System for Kitchen Fire Alarm System for Data Center

Fire Alarm System for Data Center Fire Alarm System for Coaching Institute

Fire Alarm System for Coaching Institute Fire Alarm System for Auditorium

Fire Alarm System for Auditorium